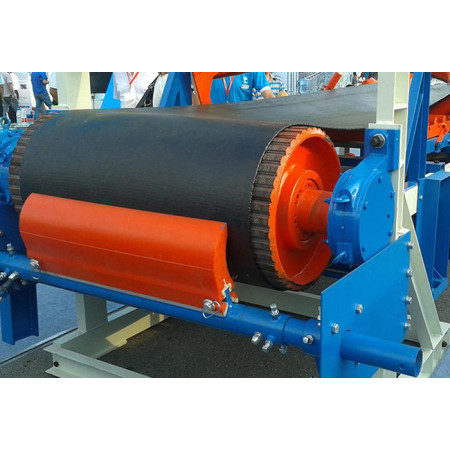

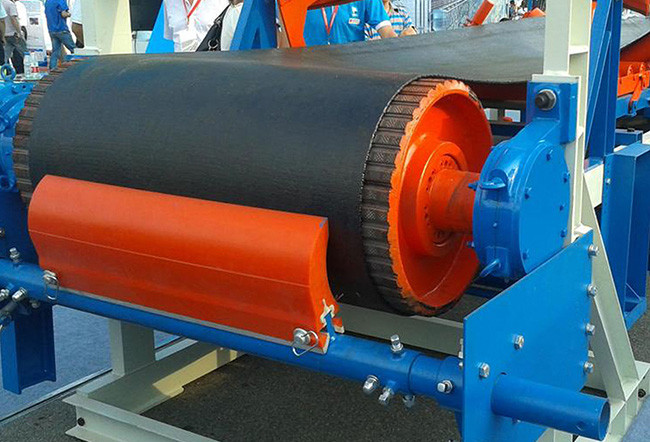

High Performance Belt Conveyor Bend Drum Pulley of Belt Conveyor Accessories

Product Description

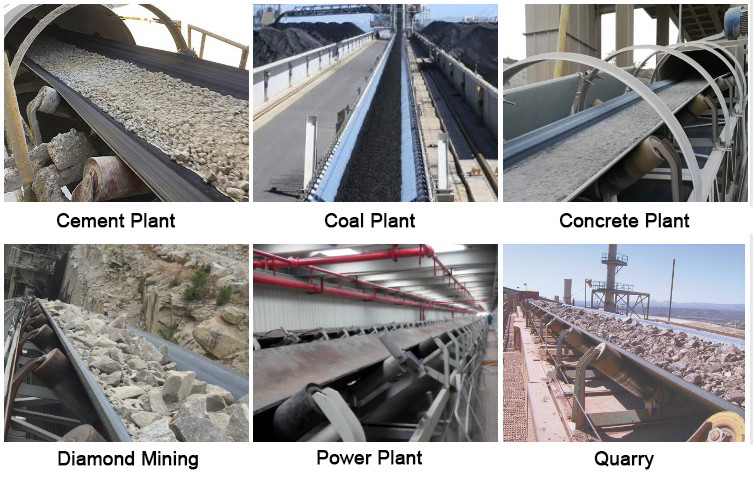

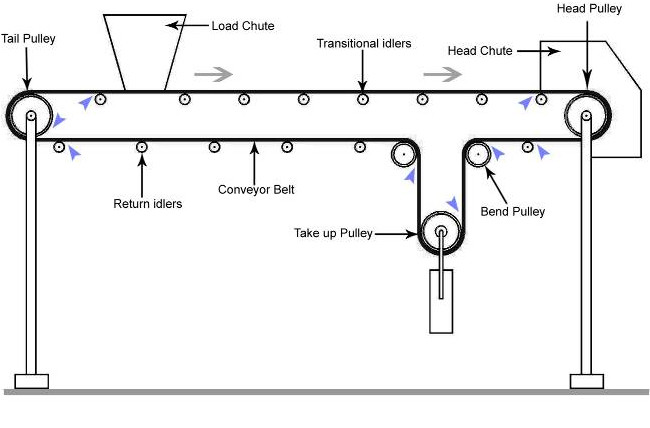

Applications:

pulleys is widely used in mining, metallurgical and coal industry to transfer sandy or lump materials, or packaged materials. The transfer system can be one single or multi-conveyors or combined with other transfer equipments according to various transferring requirements. And conveyor belt pulleys can be installed horizontally or aslope to meet the needs of different transfer lines.

Feactures:

1.The belt conveyor drum/ pulley is made by large seamless steel.

2.Use flame cutting machine to precisely cut tube.

3.Weld the pulley inner disc with professional welding machine.

4.Weld the shaft sleeve and disc with the positioner.

5.Process the outside circle with large drum lathe to guarantee the even wall thickness.

6.We select #45 round steel and sleeve to ensure the concentricity and reduction for the eccentric shaft force.

7.Equip the inner bearing enlargement device to avoid bearing damage from beating.

8.We will make the static balance inspection when the belt speed exceeds 2.5m/s.

9.We can produce different type,different standard pulley according to customers’ request.

Glossy | Rubber surface | |||||||

|---|---|---|---|---|---|---|---|---|

B | effect | Allow | D | Bearing | Moment of inertia | weight | Rotational inertia | weight |

mm | Torque | Joint force | mm | model | ||||

kN·m3 | kN | kg·m3 | kg | kg·m3 | kg | |||

500 | 2.7 | 49 | 500 | 1316 | 5 | 250 | 6 | 264 |

650 | 3.5 | 40 | 6.5 | 280 | 7.8 | 298 | ||

4.1 | 630 | 16.3 | 324 | 18.5 | 347 | |||

6.3 | 59 | 500 | 3520 | 7.8 | 432 | 9.8 | 393 | |

7.3 | 80 | 630 | 19.5 | 492 | 18.5 | 451 | ||

800 | 4.1 | 40 | 800 | 9.8 | 453 | |||

6 | 50 | 630 | 23.8 | 752 | 23.5 | 521 | ||

7 | 800 | 25 | 782 | |||||

12 | 80 | 630 | 3524 | 28.5 | 844 | 29.5 | 776 | |

800 | 58 | 887 | ||||||

20 | 100 | 630 | 3528 | 32 | 920 | |||

2x16 | 32 | 967 | ||||||

20 | 110 | 800 | 66.3 | 1095 | ||||

2x16 | 66.3 | 1143 | ||||||

32 | 160 | 3532 | 67.5 | 1253 | ||||

2x23 | 67.5 | 1287 | ||||||

1000 | 6 | 40 | 630 | 3520 | 26.5 | 585 | ||

12 | 73 | 630 | 3524 | 38.3 | 857 | |||

800 | 78.8 | 964 | ||||||

80 | 1000 | 164.8 | 1162 | |||||

20 | 110 | 800 | 3528 | 80.3 | 1168 | |||

2x16 | 80.3 | 1216 | ||||||

20 | 110 | 1000 | 3528 | 166.5 | 1408 | |||

2x16 | 166.5 | 1456 | ||||||

27 | 160 | 800 | 3532 | 81.8 | 1376 | |||

2x22 | 81.8 | 1410 | ||||||

27 | 170 | 1000 | 168.3 | 1617 | ||||

2x22 | 168.3 | 1651 | ||||||

40 | 190 | 800 | 3536 | 83.3 | 1691 | |||

2x35 | 83.3 | 1744 | ||||||

40 | 210 | 1000 | 170 | 1928 | ||||

2x35 | 170 | 1981 | ||||||

52 | 330 | 3540 | 215.3 | 2585 | ||||

2x42 | 215.3 | 2677 |

- [email protected]

- +8618916089629(WhatsApp)

- No.365 Chuanhong Road, Pudong, Shanghai, China