What are different types of idlers for belt conveyor?

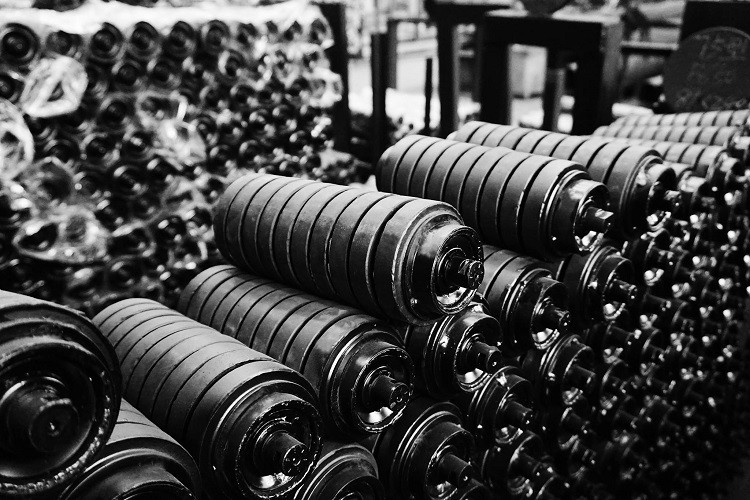

Idlers are used to support the conveyor belt and the materials on the conveyor belt to ensure the stable operation of the conveyor belt. Different types of idlers can be used for different industry applications. So what are the types of belt conveyor idlers? There are many different types conveyor idlers which can be used in many different application; SKE machinery will show you in detail.

According to the classification of idlers’ manufacturing materials, conveyor idlers can be divided into the following types: rubber idlers, ceramic idlers, nylon idlers and insulation idlers.

1. Ceramic idler: it can be used in extremely harsh environment, no static electricity, No sparks when rubbing, and is very suitable for coal-well and other operations, and it can effectively prevent belt deviation, fork pulling, heating and fire.

2. Nylon idler: no necessary oil injection, corrosion resistance, anti-aging, acid and alkali resistance, light weight, high waterproof performance, it is suitable for different occasions in the dust environment of material delivery.

The conveyor idlers can be known as the below types according to the function classification;

1. Troughed idler: the troughed idler is generally composed of two side idlers and a flat idler, with a groove angle of 30-35 degrees. For a detachable belt conveyor, the three idlers are hinged to each other, hence it is called the articulated idler. It is mainly used for carrying branch conveying bulk materials.

2.Parallel idlers: the parallel idler is generally one long idler; parallel upper idlers, which are used to carry the branch transportation of articles. It is installed at the lower end of the bearing pressure, so it is called the lower idler. The parallel lower idler is used for the return branch to support the conveyor belt.

3.Self-aligning idler: used to adjust the deviation of conveyor belt, prevent hunting and ensure the stable operation of conveyor belt. The front inclined groove roller also plays the role of Self-aligning and centering.

4.Impact idlers: installed under the loading section of the conveyor to reduce the impact on the conveyor belt and extend the service life of the conveyor belt.

5.

6.

7.

- [email protected]

- +8618916089629(WhatsApp)

- No.365 Chuanhong Road, Pudong, Shanghai, China

- Mobile Phone

- *Title

- *Content