Conveyor System Series

Belt conveyors are widely used in many fields, such as raw coal conveying, bulk material stacking, long distance conveying, stone crushing plant, mineral ore processing plant, cement plant, river port loading ,electrical power station plant etc; Single conveyor or combined by several belt conveyors can be designed based on clients' demand and project requirement;

We SKE (Shanghai Ku Qiao Equipment Co.,Ltd) can design different bulk material handling solution by using belt conveyor system; Our company has many years experience in river port loading conveyor system, stone/ mineral ore crushing plant conveyor systems, cement plant conveyor systems.

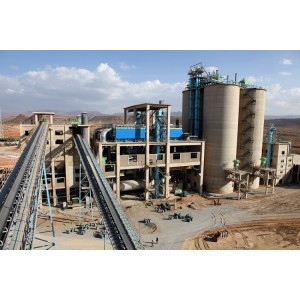

Cement Plant Conveyor System

In cement production, material transportation plays an important role in all sections of the plant from the quarry to the cement delivery station.

There are several transportation methods for conveying materials from the quarry to the storage yard: 1. Rail vehicle transportation; 2. Aerial rope-way transportation; 3. Road transportation by dump truck; 4. Transportation by belt conveyor.

And the belt conveyor is the most economic transportation system for cement plant;

Aggregate Stacking Conveyor System

The belt conveyor is a kind of friction driven equipment which transports materials in a continuous way. It is mainly composed of frame, conveyor belt, idler, pulley, tensioning device, transmission device, etc. It can form a material conveying process from the initial feeding point to the final unloading point on a certain conveying line. It can not only transport the bulk materials, but also the finished products.

Coal Handling Conveyor System

Port Stacking and loading Conveyor System

When used for barge loading, single or multi-machine combined the conveying systems are used to transport materials, which can be more than horizontal or inclined according to the requirements of the process;

The block of conveyed materials allowed by the conveyor depends on the belt width , belt speed ,the groove angle and inclination angle ,also depends on the frequency of the appearance of large pieces of material; The working environment temperature of this series of conveyors is generally: -25 ~ + 40 ℃.

Thermal power plant Conveyor System

- [email protected]

- +8618916089629(WhatsApp)

- No.365 Chuanhong Road, Pudong, Shanghai, China