Belt Conveyor Series

Belt conveyor is an ideal products used for conveying all kind of bulk material; We, SKE offers the right solution for the customer and customize the design to suit your specific requirements.

Due to different functions, there are different types of belt conveyors, such a fixed belt conveyor, mobile belt conveyor (telescopic belt conveyor), large inclined belt conveyor, long distance belt conveyor, barge loading belt conveyor and pipe belt conveyor etc; Meanwhile, based on client's different demand, the special belt conveyors ,for example, fixed conveyor with extensible device or tripper cars device, mobile conveyor with lift-able device, fixed radial conveyors, mobile radial conveyors etc can be designed by SKE company;

It can work at external temperature during -15℃~+40℃; This series conveyor is a general-purpose serial product, which uses cotton canvas, nylon, polyester canvas and steel wire belt as transporting parts. As kind of consecutive transpiration equipment;

It can be used for coal industry, metallurgical industry, mines, harbor, chemical industry, light industry, petroleum and mechanical industry, to transport various kinds of loose materials and mass materials;

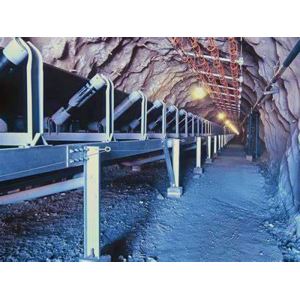

Fixed Belt Conveyor

Mobile Belt Conveyor

Universal wheels are installed at the bottom of the mobile conveyor, which can be moved at will according to the stacking position of materials. The mobile belt conveyor is used in the environment with a small conveying inclination angle. The mobile belt conveyor is a kind of equipment which is widely used in engineering, mainly used in the situations where the loading and unloading places change constantly, such as: port, wharf, station, coal yard, warehouse, construction site, sand and stone Stockyard, farm, etc

This series belt conveyors are designed to be loaded directly from wheel loaders, grab cranes, excavators etc. The mobile range can be used to stockpile material, feed auxiliary equipment, reclaim to other conveyors, directly load ships, trucks etc at production rates of up to 2500TPH.

Radial Belt Conveyor

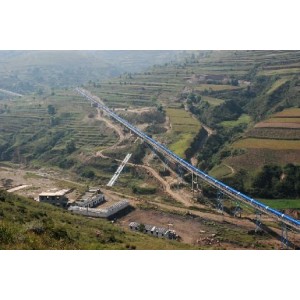

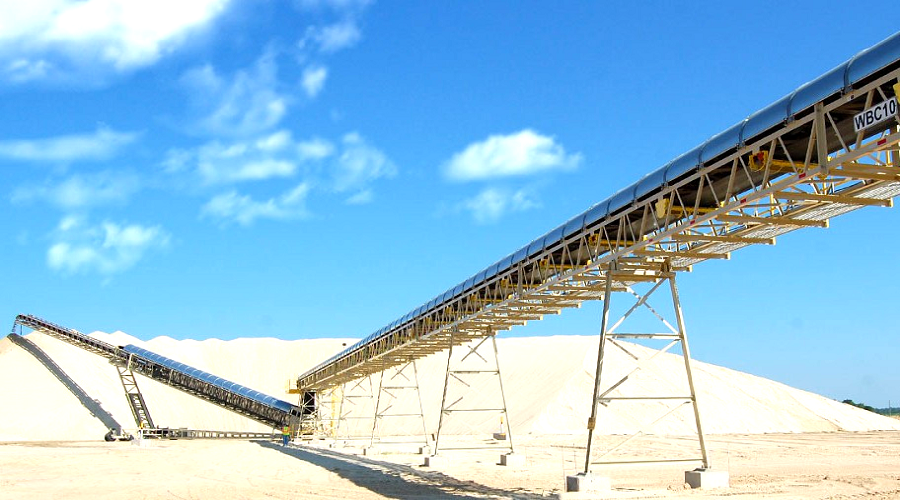

Overland Belt Conveyor

Large Inclined Belt Conveyor

SKE standardized Belt Conveyor

Telescopic Belt Conveyor

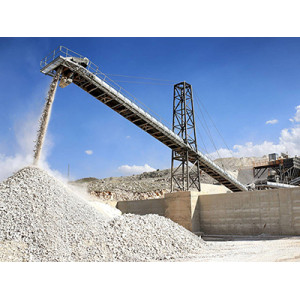

Stacking Belt Conveyor

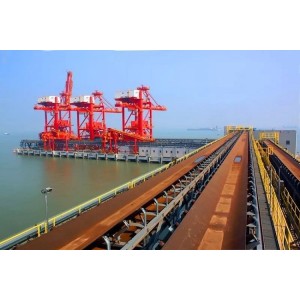

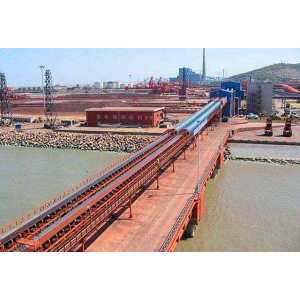

Ship Loading Belt Conveyor

Belt conveyor can be designed to be used for barge loading, single or multi-machine combined the conveying systems are used to transport materials, which can be more than horizontal or inclined according to the requirements of the process; The block of conveyed materials allowed by the conveyor depends on the belt width , belt speed ,the groove angle and inclination angle ,also depends on the frequency of the appearance of large pieces of material; The working environment temperature of this series of conveyors is generally: -25 ~ + 40 ℃.

The loading conveyors can be designed as fixed system by using steel frame with cables or mobile conveyor withe lift-able and extensible device.

Pipe Belt Conveyor

The pipe belt conveyor is a kind of special belt conveyor developed on the basis of the trough belt conveyor. Its working principle is the same as that of the ordinary belt conveyor, which is driven by friction to move the conveyor belt and its materials. Most of the components can be used in common with the ordinary belt conveyor. The difference is that the conveyor belt needs to be rolled into a round tube, so it needs to use a polygon idlers (usually a hexagon idlers) to force the conveyor belt to form a round tube, and continuously transport various loose materials such as powder, granular and block materials in a closed manner. On the basis of continuous research and practice, a set of systematic standards and methods for design, manufacture, installation, commissioning and inspection have been gradually summed up for the circular tube belt conveyor, and a series of them have been formed.

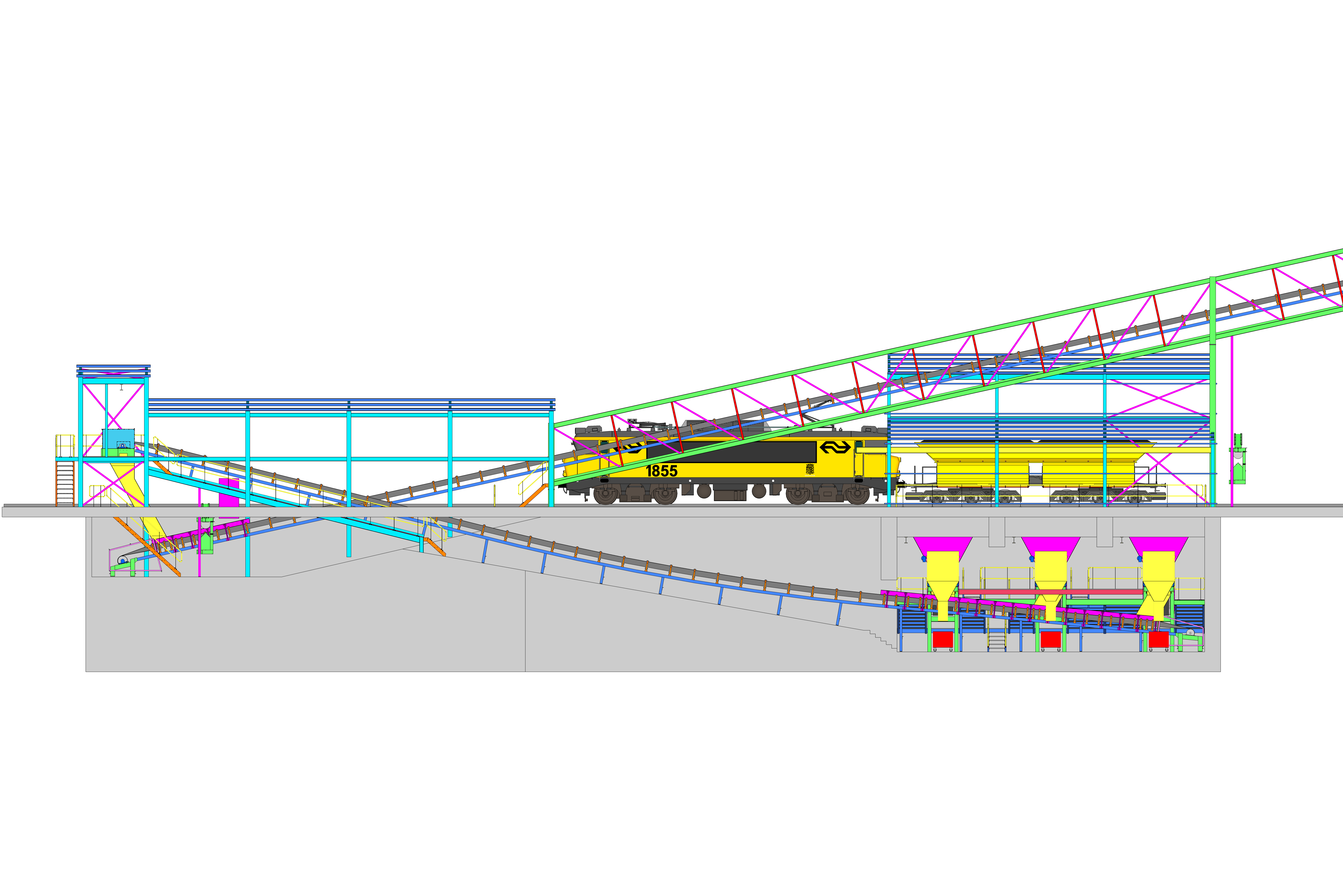

Belt conveyor for wagon unloading solution

Working procedure as below:

The bulk material discharged from the train, will go to the hopper, vibrating feeders will be set up above the belt conveyors, this part will be designed under the ground. The belt conveyors will connect other belt conveyors on the ground, and the bulk material will be transfered to other storage.

A layout of train car unloading belt Conveyor System

Applications for Train unloading Conveyor System

It is widely used in ore transporting for iron ore, copper ore, gold ore, bauxite, rare earth, coal, etc.

Belt conveyor Cases for train unloading

Garbage Belt Conveyor

- [email protected]

- +8618916089629(WhatsApp)

- No.365 Chuanhong Road, Pudong, Shanghai, China