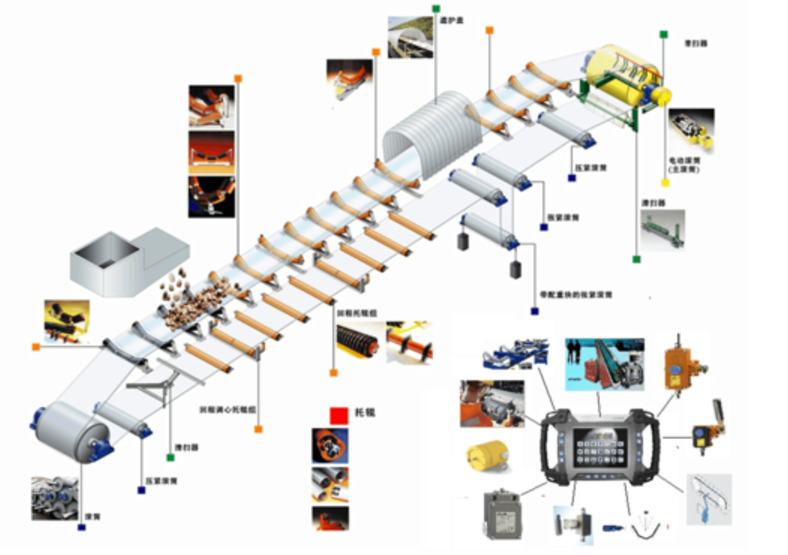

Component Series

Belt conveyor is composed by conveyor belt, drive Pulley, return pulley, carrier idlers, return idlers, steel supporting, steel frame, walkway, motor, reducer ,belt cleaner etc; They are many different types of conveyor components based on different conveyor design and requirement; All the parts are every important for a conveyor especial for a complete conveyor system, hence, good quality conveyor spare parts or components in operation or store, will influence the conveyors' normal operation.

We SKE provides complete and excellent accessories supply and services; The components we offer are: Drive Pulley, Return Pulley, Carrier Idlers, Impact Idlers, Vertical Idlers, return Idlers, conveyor belts, reducer, belt cleaners; coupling etc

Conveyor Belt

Pulley

Conveyor Pulley , called as conveyor roller , is one of the most important parts for belt conveyors; It can be designed at any point in the conveyor; It can be divided to drive pulley, return pulley , which are widely used in tail and head part of the conveyor; For a overland belt conveyor (Large inclined belt conveyor), it requires one drive pulley but many return or flour pulleys;

Idler

Belt Cleaner

Reducer

Speed reducers receive power from conveyor belt motors via their input shafts. The gearbox converts speed to torque (or vice-versa) and transmits this load to the conveyor belt via its output shaft.

SKE machinery is a professional manufacturer and exporter of industrial Gear box and electric motors and belt conveyors used for various industrial fields.

Motor

Coupling

- [email protected]

- +8618916089629(WhatsApp)

- No.365 Chuanhong Road, Pudong, Shanghai, China